Why Optical Windows are Crucial for Achieving High-Precision Measurements

Classification: Knowledge

Release time: 2026-02-19

Outline: Why Optical Windows Matter in High-Precision Measurements Table of Contents 1. Introduction to Optical Windows 2. Functionality of Optical Windows 2.1 How Optical Windows Transmit Light 2.2 Environmental Protection Offered 2.3 Importance of Optical Quality 3. Applications of Optical Windows in High-Precision Measurements 3.1 Rol

Why Optical Windows Matter in High-Precision Measurements

Table of Contents

- 1. Introduction to Optical Windows

- 2. Functionality of Optical Windows

- 2.1 How Optical Windows Transmit Light

- 2.2 Environmental Protection Offered

- 2.3 Importance of Optical Quality

- 3. Applications of Optical Windows in High-Precision Measurements

- 4. Materials Used for Optical Windows

- 5. The Role of Optical Coatings

- 6. Design Considerations for Optical Windows

- 7. Challenges in Optical Window Usage

- 8. Future Trends in Optical Windows Technology

- 9. Conclusion

- 10. Frequently Asked Questions

1. Introduction to Optical Windows

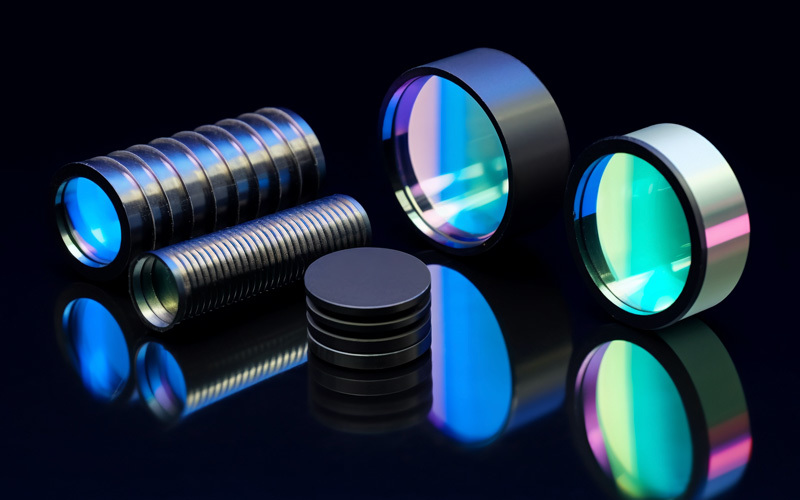

Optical windows are transparent materials that play an essential role in high-precision measurements. These components serve as barriers that allow light to pass while protecting sensitive equipment from environmental factors. Commonly used in a variety of industries, optical windows provide a critical interface between the measurement device and the external environment, making their quality and functionality paramount.

2. Functionality of Optical Windows

Optical windows are lightweight and durable, specifically designed to meet the stringent demands of high-precision applications.

2.1 How Optical Windows Transmit Light

The primary function of optical windows is to **transmit light** with minimal distortion. This capability is crucial for ensuring accurate measurements, particularly in optical systems where precision is paramount. High-quality optical windows allow for high **transmission efficiency**, crucial for applications requiring precise readings.

2.2 Environmental Protection Offered

Optical windows also serve to provide **environmental protection** for sensitive measurement instruments. By acting as a barrier, they prevent contamination from dust, moisture, and other environmental factors that could negatively impact measurement accuracy. This protective function is especially vital in laboratory settings and outdoor measurements.

2.3 Importance of Optical Quality

The **optical quality** of windows is critical in maintaining measurement integrity. Any imperfections, such as scratches or bubbles, can introduce errors in measurement. Therefore, it is essential to use high-quality, well-manufactured optical windows to minimize such risks.

3. Applications of Optical Windows in High-Precision Measurements

Optical windows find applications across various fields, underscoring their importance in high-precision measurements.

3.1 Role in Scientific Research

In scientific research, the accuracy of measurements is fundamental. Optical windows are employed in **spectroscopy, microscopy**, and other analytical techniques, allowing researchers to obtain precise data. Their ability to provide a clear path for light makes them indispensable in optical experiments.

3.2 Industrial Uses and Manufacturing

In industrial settings, optical windows are utilized in equipment like **lasers, sensors, and cameras**. Their durability and protective features enable consistent performance in harsh environments, ensuring that measurements remain precise even under challenging conditions.

3.3 Biomedical Applications

The biomedical field heavily relies on optical windows for applications such as **imaging and diagnostics**. Instruments like endoscopes and diagnostic devices depend on optical windows to ensure clarity and accuracy in visualizing biological samples.

4. Materials Used for Optical Windows

The selection of materials for optical windows is crucial for determining their performance and suitability for specific applications.

4.1 Common Materials and Their Properties

Common materials used for optical windows include **glass** and **quartz**. These materials are favored for their excellent optical properties, including high transmission rates and low absorption. Glass windows are particularly popular for general-purpose applications, while quartz is often chosen for UV applications due to its superior transmission in that range.

4.2 Advanced Materials for Specialized Applications

Advanced materials such as **sapphire** and **polymer films** provide unique advantages in specialized applications. Sapphire windows, for instance, are known for their **hardness and scratch resistance**, making them ideal for rugged environments. Meanwhile, polymer films can be tailored for specific wavelengths and are often more cost-effective than traditional materials.

5. The Role of Optical Coatings

Optical coatings enhance the performance of optical windows significantly.

5.1 Functionality of Optical Coatings

These coatings are applied to the surface of optical windows to improve their **transmission properties** and reduce unwanted reflections. By minimizing loss of light due to reflection, optical coatings ensure that more light enters the measurement system, enhancing the overall accuracy of measurements.

5.2 Different Types of Coatings and Their Benefits

Various types of optical coatings exist, including **anti-reflective coatings** and **reflective coatings**. Anti-reflective coatings are vital in reducing glare and enhancing light transmission, while reflective coatings are used in applications requiring mirrors or beam splitters.

6. Design Considerations for Optical Windows

When designing optical windows, several key considerations must be addressed to ensure optimal performance.

6.1 Dimensional Accuracy and Tolerances

**Dimensional accuracy** is critical in optical window design. Tolerances must be strictly controlled to ensure proper fitting within instruments and to avoid any degradation of optical performance. Even minor deviations can lead to significant measurement errors.

6.2 Thermal Considerations

Thermal effects can also affect the performance of optical windows. Materials chosen must be able to withstand the operational temperatures without warping or degrading. Proper thermal management ensures that optical measurements remain precise across a range of environmental conditions.

7. Challenges in Optical Window Usage

While optical windows are critical components in high-precision measurements, they are not without challenges.

Factors such as **environmental stress**, **scratching**, and **contamination** can compromise the effectiveness of optical windows. Manufacturers must continuously innovate to develop windows that maintain their integrity and performance under various conditions.

8. Future Trends in Optical Windows Technology

As technology advances, the future of optical windows looks promising. Innovations in **material science** and **coating technology** are paving the way for more efficient and effective optical windows. Research into new materials and designs will likely yield products that offer better performance in demanding applications.

9. Conclusion

Optical windows are essential components in achieving high-precision measurements across various fields. Their ability to protect sensitive equipment while allowing accurate light transmission is critical in applications ranging from scientific research to industrial manufacturing and biomedical diagnostics. As technology evolves, the role of optical windows will become increasingly significant, driving the need for continual advancements in material and design.

10. Frequently Asked Questions

1. What are optical windows used for?

Optical windows are used to allow light to pass through while protecting sensitive instruments from environmental factors. They are crucial in applications like spectroscopy, microscopy, and various industrial processes.

2. What materials are commonly used for optical windows?

Common materials include glass, quartz, and advanced options like sapphire and polymer films. The choice of material depends on the specific requirements of the application.

3. How do optical coatings enhance performance?

Optical coatings reduce reflections and enhance light transmission, thereby improving the overall accuracy of measurements taken using optical windows.

4. What challenges do optical windows face?

Challenges include environmental stress, scratching, and contamination, all of which can compromise their effectiveness and impact measurement accuracy.

5. What are some future trends in optical windows technology?

Future trends include advancements in material science and coating technology, leading to optical windows that provide enhanced performance and efficiency in various demanding applications.

keywords: Why Optical Windows are Crucial for Achieving High-Precision Measurements

Related information

Knowledge

-

Why Optical Windows are Crucial for Achieving High-Precision Measurements

Time:2026-02-19

-

Understanding the Functions and Applications of Plano-Convex Cylindrical Lenses

Time:2026-02-18

-

Understanding Different Types of Optical Filters Used in Instruments: A Comprehensive Guide

Time:2026-02-17

-

Understanding Optical Prisms: Their Functionality and Applications

Time:2026-02-16

-

Why Optical Domes are Essential for High-Quality Imaging

Time:2026-02-15

-

Understanding Aspheric Lenses: Key Innovations in Optical Instruments

Time:2026-02-14

-

Enhancing Light Transmission: The Essential Role of Ball Lenses in Optics

Time:2026-02-13

-

The Versatility of Zinc Sulfide Windows in Optical Applications

Time:2026-02-12

-

Exploring Different Types of Optical Windows and Their Uses: A Comprehensive Guide

Time:2026-02-11

-

Understanding the Plano-Convex Cylindrical Lens: Applications and Benefits

Time:2026-02-10

-

Choosing the Right Optical Filter for Your Measurement Needs: A Comprehensive Guide

Time:2026-02-09

-

Understanding Optical Prisms: Essential Tools for Precision Measurement

Time:2026-02-08

-

The Science Behind Optical Domes: A Comprehensive Exploration of Their Design and Functionality

Time:2026-02-07

-

Plano Convex Cylindrical Lens Drives Precision Advancement in Modern Optical Applications

Time:2026-02-06

-

Unlocking the Potential of Aspheric Lenses in Optical Instruments

Time:2026-02-06

-

The Science Behind Ball Lenses: Unlocking Their Functionality and Applications

Time:2026-02-05

-

The Essential Guide to Zinc Sulfide Windows in Optical Instruments

Time:2026-02-04

-

Top Considerations When Choosing an Optical Window for Your Project

Time:2026-02-03

-

Understanding Plano-Convex Cylindrical Lenses: Key Insights for Optical Instrumentation

Time:2026-02-02

-

The Science Behind Optical Filters: Applications and Benefits

Time:2026-02-01

-

Understanding Optical Prisms: A Key Component in Optical Instruments

Time:2026-01-31

-

Understanding the Role of Optical Domes in Advanced Measurement Tools

Time:2026-01-30

-

Understanding Aspheric Lenses: A Key Component in Optical Instruments

Time:2026-01-29

-

Innovative Applications of Ball Lenses in Modern Optics: Exploring the Future of Optical Technology

Time:2026-01-24

-

Understanding Zinc Sulfide Windows: Applications and Benefits in Optical Instruments

Time:2026-01-23

-

The Science Behind Optical Windows: Materials and Applications

Time:2026-01-22

-

Understanding Plano-Convex Cylindrical Lenses: Essential Insights for Optical Instrumentation

Time:2026-01-21

-

How Optical Filters Enhance Image Quality in Optical Instruments

Time:2026-01-20

-

Understanding Optical Prisms: Unveiling the Science Behind Light Manipulation

Time:2026-01-19

-

How Optical Domes Enhance Optical Performance in Instruments

Time:2026-01-18

-

Understanding Aspheric Lenses: Enhancing Optical Performance in Instrumentation

Time:2026-01-17

-

Why Ball Lenses are Essential for Precision in Optical Systems

Time:2026-01-16

-

Understanding Zinc Sulfide Windows: A Key Component in Optical Instruments

Time:2026-01-15

-

How Optical Windows Enhance Performance in Optical Instruments

Time:2026-01-14

-

Understanding Plano-Convex Cylindrical Lenses: Applications and Benefits

Time:2026-01-13

-

Exploring the Role of Optical Filters in Modern Instrumentation: Enhancing Precision and Performance

Time:2026-01-12

-

Understanding Optical Prisms: The Essentials for Instrumentation and Measurement

Time:2026-01-11

-

Exploring the Benefits of Optical Domes in Precision Instruments

Time:2026-01-10

-

The Advantages and Applications of Aspheric Lenses in Optical Instruments

Time:2026-01-09

-

Exploring the Versatility of Ball Lenses in Optical Instruments

Time:2026-01-08

-

Understanding Zinc Sulfide Windows: Key Features and Applications in Optical Instruments

Time:2026-01-07

-

Understanding the Essential Role of an Optical Window in Modern Instruments

Time:2026-01-06

-

The Growing Importance of Infrared Optical Lenses in Modern Technology

Time:2026-01-06

Blog

-

The application of CSOPT micro-optical components in the field of medical technology

Time:2025-10-31

-

"HR Coating: Enhancing Durability and Performance"

Time:2025-07-28

-

CSOPT -China Star Optics shines at the 2025 Changchun Optics Expo

Time:2025-06-27

-

Optical Manufacturing: From Glass to Precision Optics

Time:2025-05-06

-

A Tricky Question-What color is a mirror?

Time:2025-04-08

-

A Closer Look at Optical Domes: Design, Materials, and Applications

Time:2025-03-03

-

AI website building technology comes into its own: website development ushers in new changes

Time:2022-07-28

-

Continuously innovate and introduce more and better services to create intelligent Chinese enterprises and accomplish smart entrepreneurs!

Time:2022-01-10

-

Technological innovation is the key to core competitiveness

Time:2021-11-12

-

Informatization will be the way for SMEs to enhance their competitiveness

Time:2021-11-12

Exhibitions

-

Exploring New Horizons: CSOPT at Photonics Russia 2025

Time:2025-04-12

-

CSOPT at APE 2025 – Booth D106

Time:2025-02-25

-

CSOPT Successfully Concludes Participation at Optatec 2024 in Frankfurt

Time:2024-05-20

-

CSOPT Is Heading to Russia for Photonics 2024

Time:2024-03-15

-

CSOPT at APE 2024, Singapore

Time:2024-03-10

-

CSOPT will participate in SPIE Photonics West 2024

Time:2024-01-25

-

Highlights from the 24th China International Optoelectronic Exposition (CIOE)

Time:2023-09-09

-

China Star Optics Concludes a Successful Exhibition at LASER World of PHOTONICS 2023

Time:2023-06-20

Videos

Download

Previous Page: None