The Science Behind Optical Windows: Materials and Applications

Classification: Knowledge

Release time: 2026-01-22

Outline: The Science Behind Optical Windows: Materials and Applications Table of Contents 1. Introduction to Optical Windows 2. Understanding the Role of Optical Windows in Various Industries 3. Key Materials Used in Optical Windows 3.1 Glass Optical Windows 3.2 Plastic Optical Windows 3.3 Crystal Optical Windows 4. Manufacturing Processes of Optical Windows 5. Applications of Optical Windows Across Differ

The Science Behind Optical Windows: Materials and Applications

Table of Contents

1. Introduction to Optical Windows

2. Understanding the Role of Optical Windows in Various Industries

3. Key Materials Used in Optical Windows

3.1 Glass Optical Windows

3.2 Plastic Optical Windows

3.3 Crystal Optical Windows

4. Manufacturing Processes of Optical Windows

5. Applications of Optical Windows Across Different Sectors

5.1 Optical Windows in Telecommunications

5.2 Use in Medical Devices

5.3 Role in Defense and Aerospace

6. Challenges in Optical Window Design and Production

7. Future Trends in Optical Window Technology

8. FAQs About Optical Windows

9. Conclusion

1. Introduction to Optical Windows

Optical windows are crucial components in a vast range of devices, providing a barrier that allows light to pass while offering protection from environmental elements. These transparent materials serve a vital function in both commercial and industrial applications, and understanding their properties is essential for optimizing their use.

In this article, we will delve deep into the science behind optical windows, exploring various materials, their manufacturing processes, and the wide array of applications that depend on these indispensable components.

2. Understanding the Role of Optical Windows in Various Industries

Optical windows are employed extensively across numerous fields, including telecommunications, medicine, aerospace, and manufacturing. Their primary function is to facilitate the passage of light while simultaneously protecting sensitive components from physical and environmental damage. This characteristic is particularly significant in fields where precision is paramount.

The increasing reliance on optical technology drives the demand for high-performance optical windows that can withstand harsh conditions while maintaining optical clarity. As we explore the different materials and applications of optical windows, the importance of selecting the right type for specific applications becomes clear.

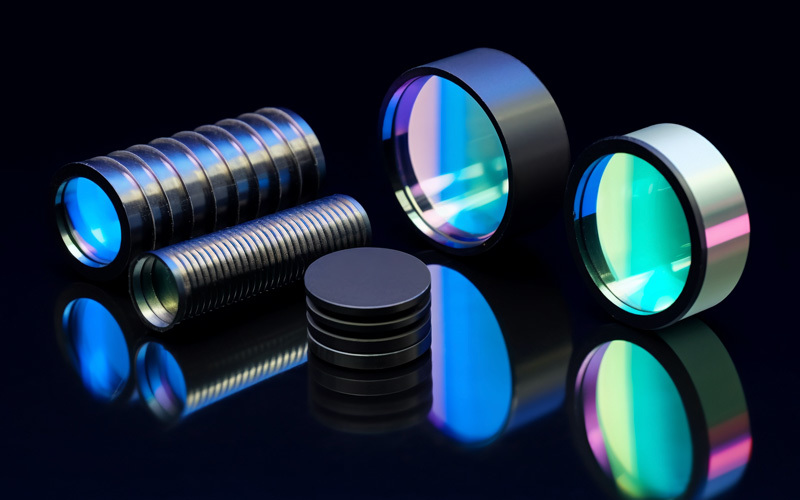

3. Key Materials Used in Optical Windows

Choosing the right material is crucial for enhancing the performance of optical windows. The primary materials include glass, plastics, and crystals, each offering unique advantages and disadvantages.

3.1 Glass Optical Windows

Glass is one of the most widely used materials for optical windows. It provides excellent optical clarity, durability, and scratch resistance. Common types of glass used include borosilicate glass and quartz glass. Borosilicate glass is known for its thermal stability, making it ideal for applications involving significant temperature fluctuations. Quartz glass, on the other hand, excels in optical transparency and is often used in high-performance applications like lasers and spectroscopes.

3.2 Plastic Optical Windows

Plastic optical windows, such as polycarbonate and acrylic, offer a lightweight and shatter-resistant alternative to glass. They are advantageous in applications where weight reduction is crucial, such as in aerospace and portable devices. While plastic windows may not match the scratch resistance of glass, advancements in coatings have significantly improved their durability and optical performance.

3.3 Crystal Optical Windows

Crystal optical windows, such as sapphire and various types of single crystals, provide the highest levels of durability and thermal resistance. Sapphire, known for its hardness and thermal stability, is particularly useful in high-energy laser applications. Crystal windows are often employed in environments that require exceptional resilience against scratches and harsh conditions.

4. Manufacturing Processes of Optical Windows

The manufacturing of optical windows is a meticulous process that requires precision and expertise. Various methods are used, depending on the material and required specifications.

1. **Cutting and Shaping:** The first step involves cutting the raw material into the desired shape and size. Laser cutting and diamond sawing are commonly employed techniques that ensure high accuracy.

2. **Polishing:** After shaping, optical windows undergo a polishing process to achieve the required surface quality. This step is critical, as surface imperfections can significantly impact optical performance. Advanced polishing techniques, such as chemical mechanical polishing (CMP), are often used to achieve the desired finish.

3. **Coating:** To enhance performance, optical windows may receive anti-reflective or protective coatings. These coatings improve light transmission and protect the surface from scratches and environmental damage.

4. **Quality Control and Testing:** Rigorous quality control measures are implemented to ensure that each window meets the necessary optical specifications. Testing may include evaluating optical clarity, refractive index, and resistance to environmental factors.

5. Applications of Optical Windows Across Different Sectors

Optical windows play a vital role in various applications, enhancing the performance and reliability of numerous devices.

5.1 Optical Windows in Telecommunications

In the telecommunications sector, optical windows are used in fiber optic systems, enabling efficient signal transmission. They are crucial in protecting sensitive components from dust, moisture, and temperature variations, ensuring uninterrupted communication.

5.2 Use in Medical Devices

Optical windows are integral to medical devices such as endoscopes and imaging systems. They provide a clear view of internal structures while safeguarding delicate instruments from contamination and damage. The biocompatibility of materials used in medical optical windows is essential for ensuring patient safety.

5.3 Role in Defense and Aerospace

In defense and aerospace applications, optical windows are designed to withstand extreme conditions. They are utilized in aircraft, satellites, and surveillance systems, where durability and optical performance are critical. Advanced materials and manufacturing processes ensure that these windows can endure harsh environments while maintaining optical clarity.

6. Challenges in Optical Window Design and Production

Despite advancements in technology, several challenges persist in the design and production of optical windows. Ensuring optical clarity while maintaining strength is a delicate balance that manufacturers must achieve. Additionally, addressing issues related to thermal stability, environmental resistance, and cost-effectiveness requires continuous innovation.

The rapid advancement of materials science also poses challenges, as new materials and techniques emerge that can disrupt traditional manufacturing processes. Staying ahead in this competitive landscape demands ongoing research and development.

7. Future Trends in Optical Window Technology

As industries continue to evolve, the future of optical window technology looks promising. Key trends include:

1. **Smart Optical Windows:** The integration of smart technologies into optical windows, such as sensors and coatings that can adapt to environmental changes, is on the rise. These innovations will enhance functionality and performance.

2. **Sustainable Materials:** The industry is shifting towards more sustainable materials, with an emphasis on reducing environmental impact. Biodegradable plastics and recycled materials are becoming more common in optical window production.

3. **Nanotechnology Applications:** The use of nanomaterials to improve the performance of optical windows is an emerging field. Nanocoatings can enhance durability, reduce weight, and improve optical properties.

8. FAQs About Optical Windows

1. What is the primary function of optical windows?

Optical windows allow light to pass through while providing protection from environmental factors and maintaining the integrity of the optical system.

2. What materials are best for optical windows?

The best materials depend on the specific application. Glass, plastic, and crystal each have unique properties that make them suitable for different uses.

3. How are optical windows manufactured?

The manufacturing process involves cutting, shaping, polishing, coating, and rigorous quality control to ensure optimal performance.

4. What are the common applications of optical windows?

Optical windows are used in telecommunications, medical devices, defense and aerospace, among other industries.

5. What challenges do manufacturers face in producing optical windows?

Manufacturers face challenges related to achieving optical clarity, thermal stability, and cost-effectiveness while keeping up with advancements in materials science.

9. Conclusion

Optical windows are essential components in a wide array of industries, providing not just functionality but also durability and protection. Understanding the materials and applications of optical windows enhances our capability to innovate and improve existing technologies. As industries continue to evolve, so too will the technologies and materials used in optical window manufacturing, paving the way for smarter, more efficient solutions in the future. The science behind optical windows is a testament to the ingenuity and foresight of engineers and scientists who strive to push the boundaries of what's possible in optics.

keywords: The Science Behind Optical Windows: Materials and Applications

Related information

Knowledge

-

The Science Behind Optical Windows: Materials and Applications

Time:2026-01-22

-

Understanding Plano-Convex Cylindrical Lenses: Essential Insights for Optical Instrumentation

Time:2026-01-21

-

How Optical Filters Enhance Image Quality in Optical Instruments

Time:2026-01-20

-

Understanding Optical Prisms: Unveiling the Science Behind Light Manipulation

Time:2026-01-19

-

How Optical Domes Enhance Optical Performance in Instruments

Time:2026-01-18

-

Understanding Aspheric Lenses: Enhancing Optical Performance in Instrumentation

Time:2026-01-17

-

Why Ball Lenses are Essential for Precision in Optical Systems

Time:2026-01-16

-

Understanding Zinc Sulfide Windows: A Key Component in Optical Instruments

Time:2026-01-15

-

How Optical Windows Enhance Performance in Optical Instruments

Time:2026-01-14

-

Understanding Plano-Convex Cylindrical Lenses: Applications and Benefits

Time:2026-01-13

-

Exploring the Role of Optical Filters in Modern Instrumentation: Enhancing Precision and Performance

Time:2026-01-12

-

Understanding Optical Prisms: The Essentials for Instrumentation and Measurement

Time:2026-01-11

-

Exploring the Benefits of Optical Domes in Precision Instruments

Time:2026-01-10

-

The Advantages and Applications of Aspheric Lenses in Optical Instruments

Time:2026-01-09

-

Exploring the Versatility of Ball Lenses in Optical Instruments

Time:2026-01-08

-

Understanding Zinc Sulfide Windows: Key Features and Applications in Optical Instruments

Time:2026-01-07

-

Understanding the Essential Role of an Optical Window in Modern Instruments

Time:2026-01-06

-

The Growing Importance of Infrared Optical Lenses in Modern Technology

Time:2026-01-06

Blog

-

The application of CSOPT micro-optical components in the field of medical technology

Time:2025-10-31

-

"HR Coating: Enhancing Durability and Performance"

Time:2025-07-28

-

CSOPT -China Star Optics shines at the 2025 Changchun Optics Expo

Time:2025-06-27

-

Optical Manufacturing: From Glass to Precision Optics

Time:2025-05-06

-

A Tricky Question-What color is a mirror?

Time:2025-04-08

-

A Closer Look at Optical Domes: Design, Materials, and Applications

Time:2025-03-03

-

AI website building technology comes into its own: website development ushers in new changes

Time:2022-07-28

-

Continuously innovate and introduce more and better services to create intelligent Chinese enterprises and accomplish smart entrepreneurs!

Time:2022-01-10

-

Technological innovation is the key to core competitiveness

Time:2021-11-12

-

Informatization will be the way for SMEs to enhance their competitiveness

Time:2021-11-12

Exhibitions

-

Exploring New Horizons: CSOPT at Photonics Russia 2025

Time:2025-04-12

-

CSOPT at APE 2025 – Booth D106

Time:2025-02-25

-

CSOPT Successfully Concludes Participation at Optatec 2024 in Frankfurt

Time:2024-05-20

-

CSOPT Is Heading to Russia for Photonics 2024

Time:2024-03-15

-

CSOPT at APE 2024, Singapore

Time:2024-03-10

-

CSOPT will participate in SPIE Photonics West 2024

Time:2024-01-25

-

Highlights from the 24th China International Optoelectronic Exposition (CIOE)

Time:2023-09-09

-

China Star Optics Concludes a Successful Exhibition at LASER World of PHOTONICS 2023

Time:2023-06-20

Videos

Download

Previous Page: None