Optical Manufacturing: From Glass to Precision Optics

Classification: Resources

Release time: 2025-05-06

Outline:

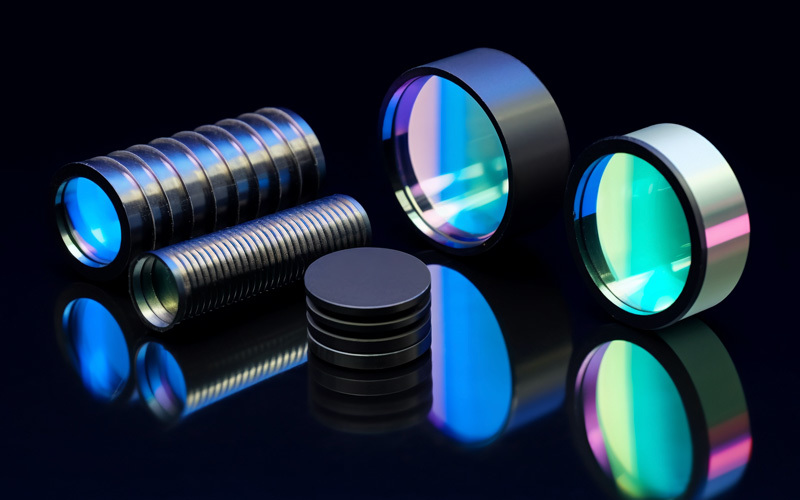

Behind every lens or prism lies a process that demands not only advanced technology, but also years of craftsmanship, discipline, and experience.

1. The Starting Point: Optical Materials

Optical components begin with carefully selected raw materials. These may include optical glass, fused silica, or crystals such as calcium fluoride (CaF₂) or zinc selenide (ZnSe), each chosen based on its transmission range, thermal stability, and refractive index. Different applications—from infrared imaging to laser systems—demand different materials to meet both optical and environmental requirements.

2. Grinding and Shaping

The rough shaping of lenses, domes, and mirrors starts with grinding, where raw blanks are processed using diamond tools to remove excess material. Whether we are crafting a spherical surface or a more complex aspheric curve, this stage is crucial in establishing the basic geometry and curvature of the component.

3. Polishing for Precision

Once the optical shape is formed, we move to polishing, where the surface is refined to achieve optical clarity and precise surface accuracy. High-end optics require surfaces with nanometer-level flatness and low surface roughness, especially for imaging, laser, or high-energy systems. For complex aspheric optics, computer-controlled polishing (CCP) techniques may be used to reach the final shape and correct micro-deviations.

4. Centering and Edging

After polishing, optics must be centered and edged, ensuring that the optical axis aligns with the mechanical axis and that dimensions meet exact specifications. In prisms, the angles must be precise; in lenses, centering impacts focal accuracy and alignment in systems.

5. Surface Coating

Many optics require thin-film coatings to enhance their transmission, reduce reflection (AR coatings), or enable wavelength-selective behavior (e.g., beamsplitters, filters). Coating design and uniformity are critical, especially in high-laser damage or wide-angle applications.

6. Inspection and Testing

Before delivery, each optic undergoes rigorous inspection using instruments like interferometers, goniometers, spectrophotometers, and CMMs. Every parameter—from surface figure and roughness to transmission rate and angle accuracy—is verified to meet customer specifications.

Why It Matters

Precision optical components are at the core of many of today’s advanced technologies—from medical imaging and aerospace to semiconductors and quantum research. Even a microscopic imperfection can impact performance. That’s why at China Star Optics, we combine decades of experience with leading-edge equipment and quality control, ensuring that every optic we produce is something you can trust.

keywords: Optical Manufacturing: From Glass to Precision Optics

Related information

Knowledge

-

Innovations in Optical Window Technology: What You Need to Know

Time:2026-03-07

-

Essential Insights into Plano-Convex Cylindrical Lenses for Optical Instrumentation

Time:2026-03-06

-

Top Factors to Consider When Selecting Optical Filters for Precision Instrumentation

Time:2026-03-05

-

Understanding Optical Prisms: The Science Behind Light Manipulation

Time:2026-03-04

-

Optical Domes: Essential Considerations for Achieving Peak Performance

Time:2026-03-03

-

The Essential Guide to Aspheric Lenses in Optical Instruments

Time:2026-03-02

-

A Deep Dive into the Manufacturing Process of Ball Lenses

Time:2026-03-01

-

Understanding Zinc Sulfide Windows: Properties and Applications in Optical Instruments

Time:2026-02-28

-

The Impact of Optical Windows on Light Transmission Efficiency: Understanding the Science Behind Optimal Performance

Time:2026-02-27

-

Understanding Plano Convex Cylindrical Lenses: Applications and Benefits in Optical Instruments

Time:2026-02-26

-

The Impact of Optical Filters on Spectroscopy Results: A Comprehensive Guide

Time:2026-02-25

-

Understanding Optical Prisms: Applications and Principles in Optical Instruments

Time:2026-02-24

-

Top Applications of Optical Domes in Modern Optical Instruments

Time:2026-02-23

-

Unlocking the Power of Aspheric Lenses in Optical Instruments

Time:2026-02-22

-

How Ball Lenses Enhance Optical Device Performance for Precision Applications

Time:2026-02-21

-

Understanding Zinc Sulfide Windows: Key Properties and Applications in Optical Instruments

Time:2026-02-20

-

Why Optical Windows are Crucial for Achieving High-Precision Measurements

Time:2026-02-19

-

Understanding the Functions and Applications of Plano-Convex Cylindrical Lenses

Time:2026-02-18

-

Understanding Different Types of Optical Filters Used in Instruments: A Comprehensive Guide

Time:2026-02-17

-

Understanding Optical Prisms: Their Functionality and Applications

Time:2026-02-16

-

Why Optical Domes are Essential for High-Quality Imaging

Time:2026-02-15

-

Understanding Aspheric Lenses: Key Innovations in Optical Instruments

Time:2026-02-14

-

Enhancing Light Transmission: The Essential Role of Ball Lenses in Optics

Time:2026-02-13

-

The Versatility of Zinc Sulfide Windows in Optical Applications

Time:2026-02-12

-

Exploring Different Types of Optical Windows and Their Uses: A Comprehensive Guide

Time:2026-02-11

-

Understanding the Plano-Convex Cylindrical Lens: Applications and Benefits

Time:2026-02-10

-

Choosing the Right Optical Filter for Your Measurement Needs: A Comprehensive Guide

Time:2026-02-09

-

Understanding Optical Prisms: Essential Tools for Precision Measurement

Time:2026-02-08

-

The Science Behind Optical Domes: A Comprehensive Exploration of Their Design and Functionality

Time:2026-02-07

-

Plano Convex Cylindrical Lens Drives Precision Advancement in Modern Optical Applications

Time:2026-02-06

-

Unlocking the Potential of Aspheric Lenses in Optical Instruments

Time:2026-02-06

-

The Science Behind Ball Lenses: Unlocking Their Functionality and Applications

Time:2026-02-05

-

The Essential Guide to Zinc Sulfide Windows in Optical Instruments

Time:2026-02-04

-

Top Considerations When Choosing an Optical Window for Your Project

Time:2026-02-03

-

Understanding Plano-Convex Cylindrical Lenses: Key Insights for Optical Instrumentation

Time:2026-02-02

-

The Science Behind Optical Filters: Applications and Benefits

Time:2026-02-01

-

Understanding Optical Prisms: A Key Component in Optical Instruments

Time:2026-01-31

-

Understanding the Role of Optical Domes in Advanced Measurement Tools

Time:2026-01-30

-

Understanding Aspheric Lenses: A Key Component in Optical Instruments

Time:2026-01-29

-

Innovative Applications of Ball Lenses in Modern Optics: Exploring the Future of Optical Technology

Time:2026-01-24

-

Understanding Zinc Sulfide Windows: Applications and Benefits in Optical Instruments

Time:2026-01-23

-

The Science Behind Optical Windows: Materials and Applications

Time:2026-01-22

-

Understanding Plano-Convex Cylindrical Lenses: Essential Insights for Optical Instrumentation

Time:2026-01-21

-

How Optical Filters Enhance Image Quality in Optical Instruments

Time:2026-01-20

-

Understanding Optical Prisms: Unveiling the Science Behind Light Manipulation

Time:2026-01-19

-

How Optical Domes Enhance Optical Performance in Instruments

Time:2026-01-18

-

Understanding Aspheric Lenses: Enhancing Optical Performance in Instrumentation

Time:2026-01-17

-

Why Ball Lenses are Essential for Precision in Optical Systems

Time:2026-01-16

-

Understanding Zinc Sulfide Windows: A Key Component in Optical Instruments

Time:2026-01-15

-

How Optical Windows Enhance Performance in Optical Instruments

Time:2026-01-14

-

Understanding Plano-Convex Cylindrical Lenses: Applications and Benefits

Time:2026-01-13

-

Exploring the Role of Optical Filters in Modern Instrumentation: Enhancing Precision and Performance

Time:2026-01-12

-

Understanding Optical Prisms: The Essentials for Instrumentation and Measurement

Time:2026-01-11

-

Exploring the Benefits of Optical Domes in Precision Instruments

Time:2026-01-10

-

The Advantages and Applications of Aspheric Lenses in Optical Instruments

Time:2026-01-09

-

Exploring the Versatility of Ball Lenses in Optical Instruments

Time:2026-01-08

-

Understanding Zinc Sulfide Windows: Key Features and Applications in Optical Instruments

Time:2026-01-07

-

Understanding the Essential Role of an Optical Window in Modern Instruments

Time:2026-01-06

-

The Growing Importance of Infrared Optical Lenses in Modern Technology

Time:2026-01-06

Blog

-

The application of CSOPT micro-optical components in the field of medical technology

Time:2025-10-31

-

"HR Coating: Enhancing Durability and Performance"

Time:2025-07-28

-

CSOPT -China Star Optics shines at the 2025 Changchun Optics Expo

Time:2025-06-27

-

Optical Manufacturing: From Glass to Precision Optics

Time:2025-05-06

-

A Tricky Question-What color is a mirror?

Time:2025-04-08

-

A Closer Look at Optical Domes: Design, Materials, and Applications

Time:2025-03-03

-

AI website building technology comes into its own: website development ushers in new changes

Time:2022-07-28

-

Continuously innovate and introduce more and better services to create intelligent Chinese enterprises and accomplish smart entrepreneurs!

Time:2022-01-10

-

Technological innovation is the key to core competitiveness

Time:2021-11-12

-

Informatization will be the way for SMEs to enhance their competitiveness

Time:2021-11-12

Exhibitions

-

Exploring New Horizons: CSOPT at Photonics Russia 2025

Time:2025-04-12

-

CSOPT at APE 2025 – Booth D106

Time:2025-02-25

-

CSOPT Successfully Concludes Participation at Optatec 2024 in Frankfurt

Time:2024-05-20

-

CSOPT Is Heading to Russia for Photonics 2024

Time:2024-03-15

-

CSOPT at APE 2024, Singapore

Time:2024-03-10

-

CSOPT will participate in SPIE Photonics West 2024

Time:2024-01-25

-

Highlights from the 24th China International Optoelectronic Exposition (CIOE)

Time:2023-09-09

-

China Star Optics Concludes a Successful Exhibition at LASER World of PHOTONICS 2023

Time:2023-06-20