Top Considerations When Choosing an Optical Window for Your Project

Classification: Knowledge

Release time: 2026-02-03

Outline: Top Considerations When Choosing an Optical Window for Your Project Choosing the right optical window is crucial for the success of any project involving optics and instrumentation. Whether you're designing a new device or upgrading an existing one, understanding the factors that influence the performance of optical windows can significantly affect the outcomes of your project. This guide explores

Top Considerations When Choosing an Optical Window for Your Project

Choosing the right optical window is crucial for the success of any project involving optics and instrumentation. Whether you're designing a new device or upgrading an existing one, understanding the factors that influence the performance of optical windows can significantly affect the outcomes of your project. This guide explores the top considerations, ensuring you make a well-informed decision.

Table of Contents

1. Understanding Optical Windows: Definition and Purpose

2. Types of Optical Windows: An Overview

3. Material Selection: Glass vs. Plastic vs. Crystal

4. Thickness and Dimensions: Finding the Right Fit

5. Coatings and Treatments: Enhancing Performance

6. Environmental Considerations: Temperature and Humidity

7. Application-Specific Factors: Tailoring Your Choice

8. Cost vs. Performance: Balancing Your Budget

9. Conclusion

10. FAQs

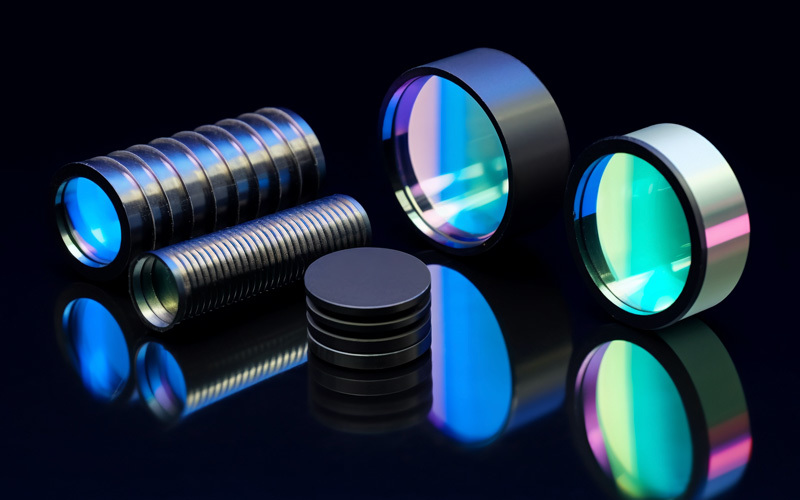

Understanding Optical Windows: Definition and Purpose

Optical windows are transparent materials that allow light to pass through without significant distortion or absorption. They serve a critical role in various applications, including scientific instrumentation, telecommunications, and medical devices. The primary purpose of an optical window is to isolate different environments while permitting light to transmit with minimal interference, thereby optimizing the performance of optical systems.

Types of Optical Windows: An Overview

There are several types of optical windows available, each designed for specific applications. Understanding the differences among them is essential for selecting the appropriate window for your project.

Standard Optical Windows

Standard optical windows are flat, thin panes of material used in various optical systems. They are often made from materials like glass or plastic and are ideal for applications that do not require specialized features.

Infrared Windows

Infrared optical windows are designed specifically for applications in the infrared spectrum. These windows are typically made from materials like germanium or zinc selenide, which are transparent to infrared radiation.

UV Windows

UV optical windows allow ultraviolet light to pass through while blocking other wavelengths. These windows are commonly made from quartz or specialized glass and are used in applications such as sterilization and photolithography.

Laser Windows

Laser windows are designed to withstand high-intensity laser light. They often feature coatings that minimize reflections and maximize transmission, ensuring optimal laser performance.

Material Selection: Glass vs. Plastic vs. Crystal

The material used for an optical window significantly impacts its performance and suitability for specific applications. Here’s a breakdown of the most common materials:

Glass

Glass is a widely used material for optical windows due to its excellent optical clarity and durability. It can be manufactured to meet various specifications, making it suitable for standard applications. However, glass can be heavy and may not perform well in environments requiring high impact resistance.

Plastic

Plastic optical windows are lightweight and can be produced in various shapes and sizes. They are often more impact-resistant than glass but may not offer the same level of optical clarity. Common plastics used include acrylic and polycarbonate, making them ideal for applications where weight is a concern.

Crystal

Crystal optical windows, such as those made from sapphire or calcium fluoride, offer superior optical performance, especially in demanding environments like high temperatures or extreme pressure. However, these materials can be more expensive and may require specialized manufacturing techniques.

Thickness and Dimensions: Finding the Right Fit

The thickness and dimensions of an optical window are critical factors that affect its optical performance, durability, and fit within your project.

Thickness

The thickness of the optical window should be chosen based on the intended application and the material used. Thicker windows can provide better durability and resistance to environmental factors, but they may also increase weight and optical distortion.

Dimensions

Customizing the dimensions of an optical window is often necessary to ensure a proper fit in your device. It’s essential to consider both the physical constraints of your assembly and the optical requirements of your application.

Coatings and Treatments: Enhancing Performance

Coatings on optical windows can significantly enhance their performance by improving transmission, reducing reflection, and providing protection against environmental factors.

Anti-Reflective Coatings

Anti-reflective coatings are designed to minimize reflections on the surface of the optical window, maximizing the amount of light transmitted through it. These coatings are particularly beneficial in applications where light loss can critically affect performance.

Protective Coatings

Protective coatings can guard against scratches, dirt, and other contaminants that may impair the optical window’s performance. These coatings can be essential in harsh environments where the window may be subject to physical damage.

Environmental Considerations: Temperature and Humidity

When selecting an optical window, it is crucial to consider the environmental conditions in which it will be used.

Temperature Variations

Extreme temperatures can affect the physical properties of optical windows, leading to warping, cracking, or changes in optical performance. Choosing materials that can withstand the expected temperature range is vital for ensuring reliability.

Humidity and Moisture

Optical windows exposed to high humidity or moisture can suffer from condensation and other issues that can impact performance. Sealing and treating the window or selecting materials resistant to moisture is essential for maintaining optical integrity.

Application-Specific Factors: Tailoring Your Choice

Different applications have unique requirements that can influence the choice of an optical window.

Scientific Research

In scientific research, optical windows may need to provide high levels of clarity and durability. The choice of material and coatings will often depend on the specific wavelengths being studied.

Industrial Applications

Industrial settings may require optical windows that can withstand harsh conditions, such as high pressures, chemicals, or extreme temperatures. Custom solutions may be necessary for optimal performance.

Cost vs. Performance: Balancing Your Budget

While it's essential to select an optical window that meets all performance criteria, budget constraints often play a significant role in the decision-making process.

Evaluating Total Cost of Ownership

Consider not only the initial purchase price but also the long-term performance and reliability of the optical window. Investing in a higher-quality window may lead to cost savings over time through reduced maintenance and replacement.

Finding the Right Balance

Strike a balance between cost and performance by assessing the specific needs of your project. Determine which features are essential and where compromises can be made without sacrificing performance.

Conclusion

Selecting the right optical window for your project is a multifaceted decision that requires careful consideration of various factors, including material selection, thickness, coatings, and environmental conditions. By understanding these factors and tailoring your choice to the specific requirements of your application, you can ensure optimal performance and reliability, ultimately contributing to your project's success.

FAQs

1. What is an optical window, and why is it important?

An optical window is a transparent material that allows light to pass through while minimizing distortion and absorption. It's essential for isolating different environments in optical systems.

2. What materials are commonly used for optical windows?

Common materials include glass, plastic, and crystal, each offering different benefits in terms of optical clarity, weight, and durability.

3. How do coatings enhance the performance of optical windows?

Coatings, such as anti-reflective and protective coatings, improve light transmission, reduce reflection, and protect against environmental damage.

4. What factors should I consider regarding environmental conditions?

Consider temperature variations and humidity levels that could affect the optical window's performance and longevity.

5. How can I balance cost and performance when choosing an optical window?

Evaluate both the initial purchase price and the total cost of ownership, including maintenance and replacement costs, to find the right balance for your project.

By keeping these considerations in mind, you'll be better equipped to choose the optical window that best meets the specific needs of your project.

keywords: Top Considerations When Choosing an Optical Window for Your Project

Related information

Knowledge

-

Top Considerations When Choosing an Optical Window for Your Project

Time:2026-02-03

-

Understanding Plano-Convex Cylindrical Lenses: Key Insights for Optical Instrumentation

Time:2026-02-02

-

The Science Behind Optical Filters: Applications and Benefits

Time:2026-02-01

-

Understanding Optical Prisms: A Key Component in Optical Instruments

Time:2026-01-31

-

Understanding the Role of Optical Domes in Advanced Measurement Tools

Time:2026-01-30

-

Understanding Aspheric Lenses: A Key Component in Optical Instruments

Time:2026-01-29

-

Innovative Applications of Ball Lenses in Modern Optics: Exploring the Future of Optical Technology

Time:2026-01-24

-

Understanding Zinc Sulfide Windows: Applications and Benefits in Optical Instruments

Time:2026-01-23

-

The Science Behind Optical Windows: Materials and Applications

Time:2026-01-22

-

Understanding Plano-Convex Cylindrical Lenses: Essential Insights for Optical Instrumentation

Time:2026-01-21

-

How Optical Filters Enhance Image Quality in Optical Instruments

Time:2026-01-20

-

Understanding Optical Prisms: Unveiling the Science Behind Light Manipulation

Time:2026-01-19

-

How Optical Domes Enhance Optical Performance in Instruments

Time:2026-01-18

-

Understanding Aspheric Lenses: Enhancing Optical Performance in Instrumentation

Time:2026-01-17

-

Why Ball Lenses are Essential for Precision in Optical Systems

Time:2026-01-16

-

Understanding Zinc Sulfide Windows: A Key Component in Optical Instruments

Time:2026-01-15

-

How Optical Windows Enhance Performance in Optical Instruments

Time:2026-01-14

-

Understanding Plano-Convex Cylindrical Lenses: Applications and Benefits

Time:2026-01-13

-

Exploring the Role of Optical Filters in Modern Instrumentation: Enhancing Precision and Performance

Time:2026-01-12

-

Understanding Optical Prisms: The Essentials for Instrumentation and Measurement

Time:2026-01-11

-

Exploring the Benefits of Optical Domes in Precision Instruments

Time:2026-01-10

-

The Advantages and Applications of Aspheric Lenses in Optical Instruments

Time:2026-01-09

-

Exploring the Versatility of Ball Lenses in Optical Instruments

Time:2026-01-08

-

Understanding Zinc Sulfide Windows: Key Features and Applications in Optical Instruments

Time:2026-01-07

-

Understanding the Essential Role of an Optical Window in Modern Instruments

Time:2026-01-06

-

The Growing Importance of Infrared Optical Lenses in Modern Technology

Time:2026-01-06

Blog

-

The application of CSOPT micro-optical components in the field of medical technology

Time:2025-10-31

-

"HR Coating: Enhancing Durability and Performance"

Time:2025-07-28

-

CSOPT -China Star Optics shines at the 2025 Changchun Optics Expo

Time:2025-06-27

-

Optical Manufacturing: From Glass to Precision Optics

Time:2025-05-06

-

A Tricky Question-What color is a mirror?

Time:2025-04-08

-

A Closer Look at Optical Domes: Design, Materials, and Applications

Time:2025-03-03

-

AI website building technology comes into its own: website development ushers in new changes

Time:2022-07-28

-

Continuously innovate and introduce more and better services to create intelligent Chinese enterprises and accomplish smart entrepreneurs!

Time:2022-01-10

-

Technological innovation is the key to core competitiveness

Time:2021-11-12

-

Informatization will be the way for SMEs to enhance their competitiveness

Time:2021-11-12

Exhibitions

-

Exploring New Horizons: CSOPT at Photonics Russia 2025

Time:2025-04-12

-

CSOPT at APE 2025 – Booth D106

Time:2025-02-25

-

CSOPT Successfully Concludes Participation at Optatec 2024 in Frankfurt

Time:2024-05-20

-

CSOPT Is Heading to Russia for Photonics 2024

Time:2024-03-15

-

CSOPT at APE 2024, Singapore

Time:2024-03-10

-

CSOPT will participate in SPIE Photonics West 2024

Time:2024-01-25

-

Highlights from the 24th China International Optoelectronic Exposition (CIOE)

Time:2023-09-09

-

China Star Optics Concludes a Successful Exhibition at LASER World of PHOTONICS 2023

Time:2023-06-20

Videos

Download

Previous Page: None