How Optical Windows Enhance Performance in Optical Instruments

Classification: Knowledge

Release time: 2026-01-14

Outline: How Optical Windows Enhance Performance in Optical Instruments In the realm of optical instrumentation, the precision and clarity of the components are paramount. Optical windows play a crucial role in determining the performance and efficiency of these instruments. These windows, often made of various optical materials, serve multiple purposes, from protecting sensitive components to facilitating

How Optical Windows Enhance Performance in Optical Instruments

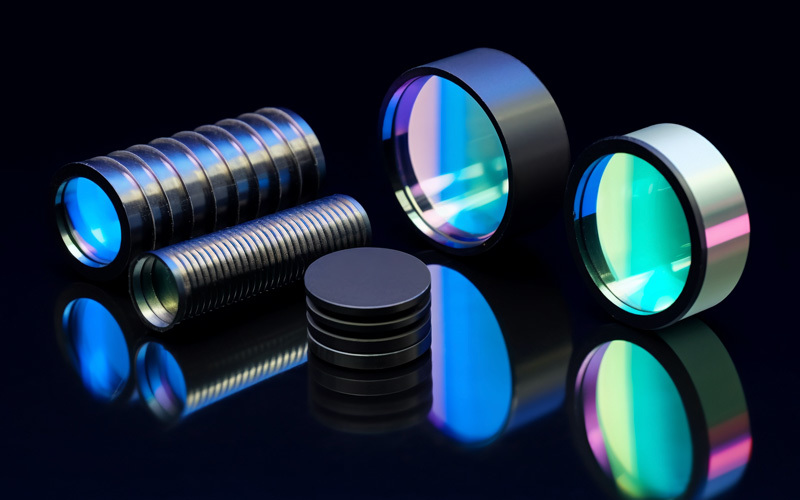

In the realm of optical instrumentation, the precision and clarity of the components are paramount. Optical windows play a crucial role in determining the performance and efficiency of these instruments. These windows, often made of various optical materials, serve multiple purposes, from protecting sensitive components to facilitating light transmission critical for analysis and measurement. In this article, we will delve deep into the significance of optical windows, examining their types, materials, applications, and how they enhance the overall performance of optical instruments.

Table of Contents

- Understanding Optical Windows

- Types of Optical Windows

- Materials Used in Optical Windows

- The Role of Optical Windows in Performance Enhancement

- Applications of Optical Windows in Various Industries

- Choosing the Right Optical Window for Your Instrument

- FAQs about Optical Windows

- Conclusion

Understanding Optical Windows

Optical windows are transparent panes that allow light to pass through while providing protection for sensitive optical elements and systems. They can be found in various optical instruments, including microscopes, telescopes, cameras, and laser systems. The primary function of optical windows is to maintain the quality of the optical path while shielding the interior components from contaminants, physical damage, and environmental factors.

Types of Optical Windows

Several types of optical windows are available, each designed for specific applications and performance requirements. Here are the most commonly used types:

Standard Optical Windows

Standard optical windows are used in a wide range of applications and are typically made from common materials like glass or plastic. They are cost-effective solutions for general use.

High-Precision Optical Windows

High-precision optical windows are manufactured to stringent tolerances and are often used in specialized applications where optical performance is critical. These windows are utilized in applications such as high-resolution imaging and spectroscopy.

Coated Optical Windows

Coated optical windows have anti-reflective or reflective coatings applied to their surfaces. These coatings enhance light transmission and reduce unwanted reflections, making them ideal for high-performance applications.

Custom Optical Windows

Custom optical windows are designed and manufactured to meet specific customer requirements. These may include unique shapes, sizes, or materials tailored for particular instruments or experimental setups.

Materials Used in Optical Windows

The choice of material for optical windows greatly influences their performance. Here are some commonly used materials:

Glass

Glass is one of the most common materials for optical windows due to its excellent optical properties and durability. Different types of glass, such as soda-lime, borosilicate, and quartz, offer varying transmission characteristics suitable for different wavelengths of light.

Fused Silica

Fused silica is a high-purity glass with exceptional optical clarity and resistance to thermal shock. It is often used in applications requiring high-performance optical windows, especially in the ultraviolet (UV) range.

Plastic

Plastic optical windows, made from materials like polycarbonate or acrylic, are lightweight and shatter-resistant. While they may not match the optical clarity of glass, they are suitable for applications where weight and durability are more critical than precision.

Crystals

Optical crystals, such as calcium fluoride (CaF2) and magnesium fluoride (MgF2), are used in high-performance optical windows. These materials exhibit excellent transmission in the UV and infrared (IR) spectra and are often used in sophisticated applications like lasers and spectroscopy.

The Role of Optical Windows in Performance Enhancement

Optical windows significantly enhance the performance of optical instruments through several mechanisms:

Light Transmission Efficiency

High-quality optical windows allow maximum light transmission, ensuring that the light entering the optical instrument is not significantly attenuated. This is particularly important in imaging systems, where clarity and brightness are crucial for accurate analysis.

Protection from Environmental Factors

Optical windows serve as barriers against dust, moisture, and other environmental contaminants. This protective role ensures that the optical systems maintain their performance over time, reducing the need for maintenance and repair.

Minimizing Optical Distortions

Precision-engineered optical windows minimize optical distortions that can arise from irregularities in the window material or surface. This accuracy is essential in applications requiring high-resolution imaging and measurement.

Enhancements through Coatings

Coatings applied to optical windows can significantly improve their performance. Anti-reflective coatings, for example, reduce reflections at the surface, enhancing light transmission. Reflective coatings can be used to direct light in specific directions, enhancing instrument functionality.

Applications of Optical Windows in Various Industries

Optical windows find applications across multiple industries, reflecting their versatility and importance. Here are some key sectors where they play a significant role:

Medical Imaging

In medical imaging systems, optical windows are used in devices such as endoscopes and ultrasound machines. They ensure clear imaging while protecting sensitive components from bodily fluids and contamination.

Telecommunications

Optical windows are crucial in fiber optics and telecommunications systems, where they facilitate signal transmission while safeguarding the optical fibers from external elements.

Aerospace and Defense

In aerospace and defense applications, optical windows are integrated into laser systems, sensors, and surveillance equipment. Their durability and reliability are essential for performance under challenging conditions.

Research and Development

Research laboratories rely on optical windows for experiments involving lasers, spectroscopy, and other optical devices. Custom optical windows are often designed to meet the unique requirements of specific research projects.

Choosing the Right Optical Window for Your Instrument

Selecting the appropriate optical window involves considering several factors to ensure optimal performance:

Wavelength Range

Determine the wavelength range of the application to select a material that provides sufficient transmission for the desired wavelengths.

Environmental Conditions

Consider the environmental conditions in which the optical window will operate. Windows need to be durable enough to withstand temperature fluctuations, humidity, and potential physical impacts.

Coatings and Surface Treatment

Evaluate whether coatings are necessary based on the specific application requirements. Anti-reflective coatings can improve performance in high-precision applications.

Size and Shape

Custom shapes and sizes may be required for specific instruments. Ensure that the selected window fits the design of the optical system appropriately.

FAQs about Optical Windows

1. What are optical windows used for?

Optical windows are used in various optical instruments to allow light transmission while protecting internal components from contamination and damage.

2. How do coatings enhance optical windows?

Coatings, such as anti-reflective or reflective coatings, improve light transmission and reduce reflections, enhancing the overall performance of optical windows.

3. What materials are best for optical windows?

Common materials for optical windows include glass, fused silica, plastic, and optical crystals, each chosen based on specific application requirements.

4. Can I customize optical windows?

Yes, optical windows can be customized based on shape, size, and material to meet specific application needs.

5. How do I maintain optical windows?

Maintaining optical windows involves cleaning them with appropriate solvents and avoiding abrasive materials that could scratch the surface.

Conclusion

In summary, optical windows are indispensable components in optical instruments, enhancing their performance through efficient light transmission, protection against environmental factors, and minimization of optical distortions. By understanding the types, materials, and applications of optical windows, professionals can make informed decisions that optimize the functionality of their optical systems. Whether in medical imaging, telecommunications, or aerospace, the strategic use of optical windows can lead to significant improvements in performance and reliability. Investing in the right optical window will undoubtedly yield benefits in precision, durability, and overall instrument efficacy.

keywords: How Optical Windows Enhance Performance in Optical Instruments

Related information

Knowledge

-

Understanding Plano-Convex Cylindrical Lenses: Essential Insights for Optical Instrumentation

Time:2026-01-21

-

How Optical Filters Enhance Image Quality in Optical Instruments

Time:2026-01-20

-

Understanding Optical Prisms: Unveiling the Science Behind Light Manipulation

Time:2026-01-19

-

How Optical Domes Enhance Optical Performance in Instruments

Time:2026-01-18

-

Understanding Aspheric Lenses: Enhancing Optical Performance in Instrumentation

Time:2026-01-17

-

Why Ball Lenses are Essential for Precision in Optical Systems

Time:2026-01-16

-

Understanding Zinc Sulfide Windows: A Key Component in Optical Instruments

Time:2026-01-15

-

How Optical Windows Enhance Performance in Optical Instruments

Time:2026-01-14

-

Understanding Plano-Convex Cylindrical Lenses: Applications and Benefits

Time:2026-01-13

-

Exploring the Role of Optical Filters in Modern Instrumentation: Enhancing Precision and Performance

Time:2026-01-12

-

Understanding Optical Prisms: The Essentials for Instrumentation and Measurement

Time:2026-01-11

-

Exploring the Benefits of Optical Domes in Precision Instruments

Time:2026-01-10

-

The Advantages and Applications of Aspheric Lenses in Optical Instruments

Time:2026-01-09

-

Exploring the Versatility of Ball Lenses in Optical Instruments

Time:2026-01-08

-

Understanding Zinc Sulfide Windows: Key Features and Applications in Optical Instruments

Time:2026-01-07

-

Understanding the Essential Role of an Optical Window in Modern Instruments

Time:2026-01-06

-

The Growing Importance of Infrared Optical Lenses in Modern Technology

Time:2026-01-06

Blog

-

The application of CSOPT micro-optical components in the field of medical technology

Time:2025-10-31

-

"HR Coating: Enhancing Durability and Performance"

Time:2025-07-28

-

CSOPT -China Star Optics shines at the 2025 Changchun Optics Expo

Time:2025-06-27

-

Optical Manufacturing: From Glass to Precision Optics

Time:2025-05-06

-

A Tricky Question-What color is a mirror?

Time:2025-04-08

-

A Closer Look at Optical Domes: Design, Materials, and Applications

Time:2025-03-03

-

AI website building technology comes into its own: website development ushers in new changes

Time:2022-07-28

-

Continuously innovate and introduce more and better services to create intelligent Chinese enterprises and accomplish smart entrepreneurs!

Time:2022-01-10

-

Technological innovation is the key to core competitiveness

Time:2021-11-12

-

Informatization will be the way for SMEs to enhance their competitiveness

Time:2021-11-12

Exhibitions

-

Exploring New Horizons: CSOPT at Photonics Russia 2025

Time:2025-04-12

-

CSOPT at APE 2025 – Booth D106

Time:2025-02-25

-

CSOPT Successfully Concludes Participation at Optatec 2024 in Frankfurt

Time:2024-05-20

-

CSOPT Is Heading to Russia for Photonics 2024

Time:2024-03-15

-

CSOPT at APE 2024, Singapore

Time:2024-03-10

-

CSOPT will participate in SPIE Photonics West 2024

Time:2024-01-25

-

Highlights from the 24th China International Optoelectronic Exposition (CIOE)

Time:2023-09-09

-

China Star Optics Concludes a Successful Exhibition at LASER World of PHOTONICS 2023

Time:2023-06-20